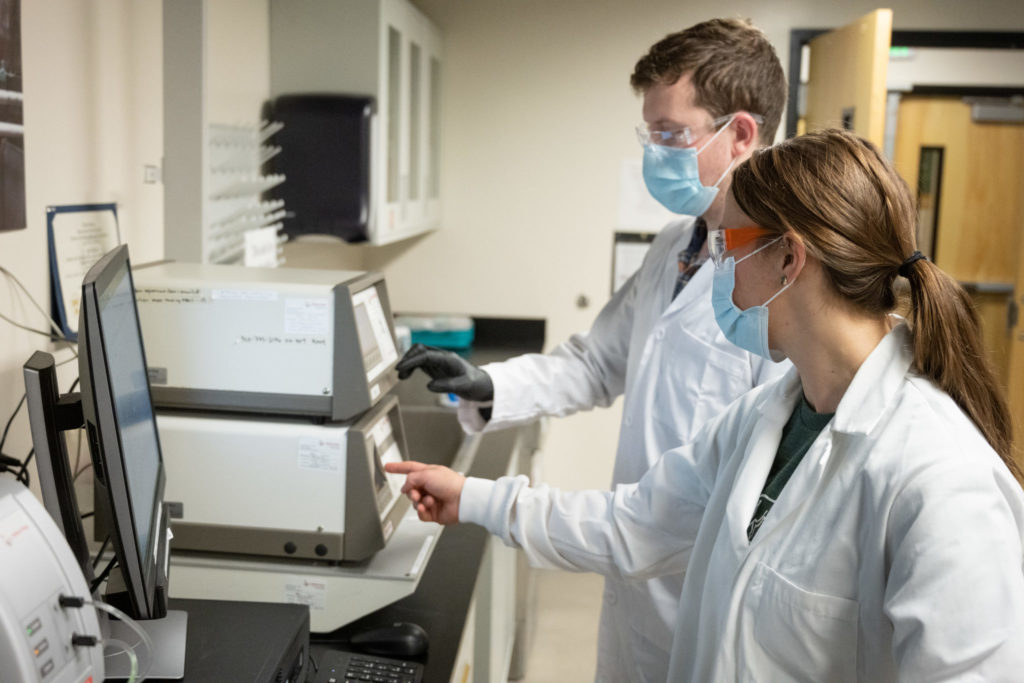

New Belgium Brewing Fermentation Science and Technology Lab Manager Katie Fromuth, left, with fourth-year fermentation science and technology major Leo Kisla. Photos by John Eisele

Barley is one of the basic ingredients in beer, but before brewing can begin, the barley must be malted – a process that starts by triggering the growth of barley seeds.

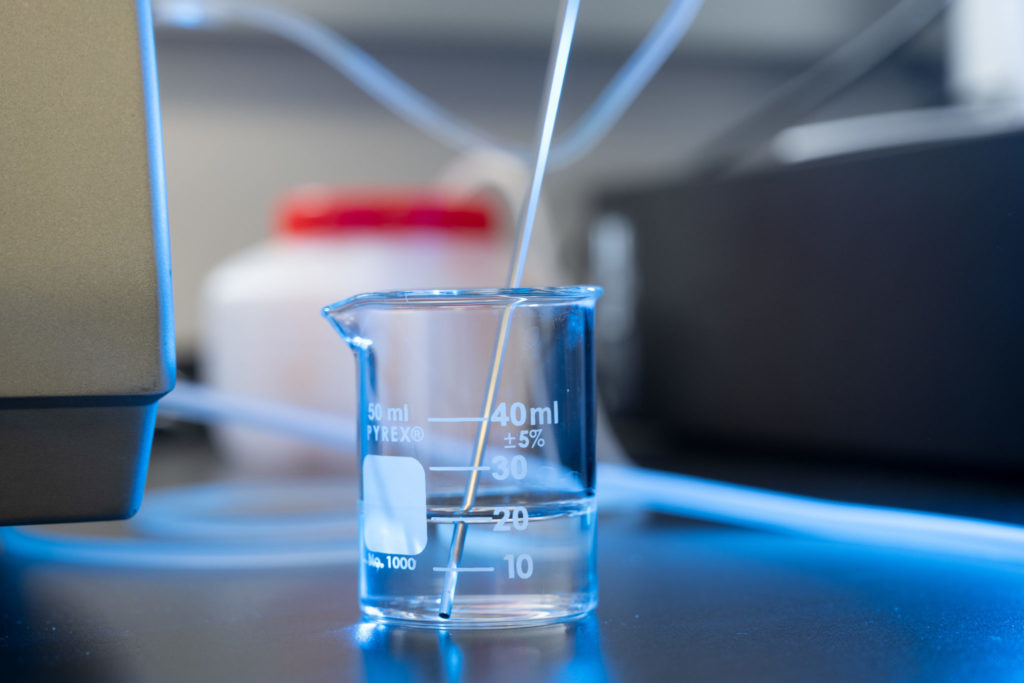

That key step in the brewing supply chain involves steeping barley kernels in water with forced air to get them to germinate. During germination, the seed generates enzymes that break down proteins and starches. But before the barley seed gets too far along in its attempt to sprout, maltsters dry and heat the kernels by “kilning,” which halts the process and preserves the enzymes.

The result is malted barley. The preserved enzymes are important to brewers because they will break down complex starches into bite-sized sugars that the yeast will then feed on during fermentation. To access the enzymes, brewers crush the malted barley and add it to hot water, where the enzymes are activated and begin breaking down starches.

Colorado State University recently became one of three campuses in the country that is home to a malt-testing lab that can analyze and certify the qualities of malted barley for the maltsters who made it — and the brewers who buy and use it for their beers.

‘An art and a science’

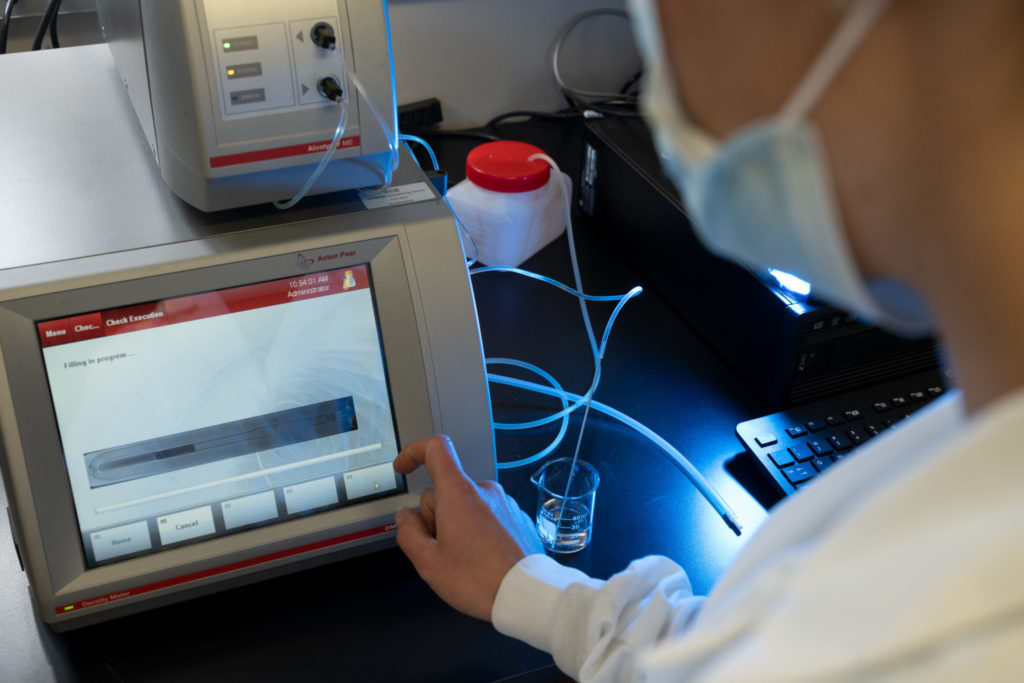

CSU’s new Malt Quality Testing Laboratory, adjacent to the New Belgium Brewing Fermentation Science and Technology Lab in the Gifford Building, began operating this summer under the supervision of Lab Manager Katie Fromuth.

“We’re kind of hijacking this natural process when we’re malting barley,” she explained. “It’s a very controlled system, and a step that has to happen before you can make beer. It’s really a craft, an art and a science in itself.”

The way barley is malted affects the alcohol, color and flavor of a beer, and can incorporate attributes such as chocolate, honey and caramel.

The malt-testing lab, located in a new room off the Anheuser-Busch Foundation Quality Laboratory, was launched with donor contributions and is a self-funded fee-for-service operation, filling a niche that maltsters and brewers in the region have been requesting.

“We’re bridging that gap between the maltster and the brewer,” Fromuth said. “We started this lab based on feedback we received from maltsters.”

In Colorado alone there are many craft maltsters who will benefit from this service, including Root Shoot Malting, Troubadour Maltings and Grouse Malt House, which have all provided malts to CSU’s Fermentation Science and Technology program for brewing.

‘Field to foam’

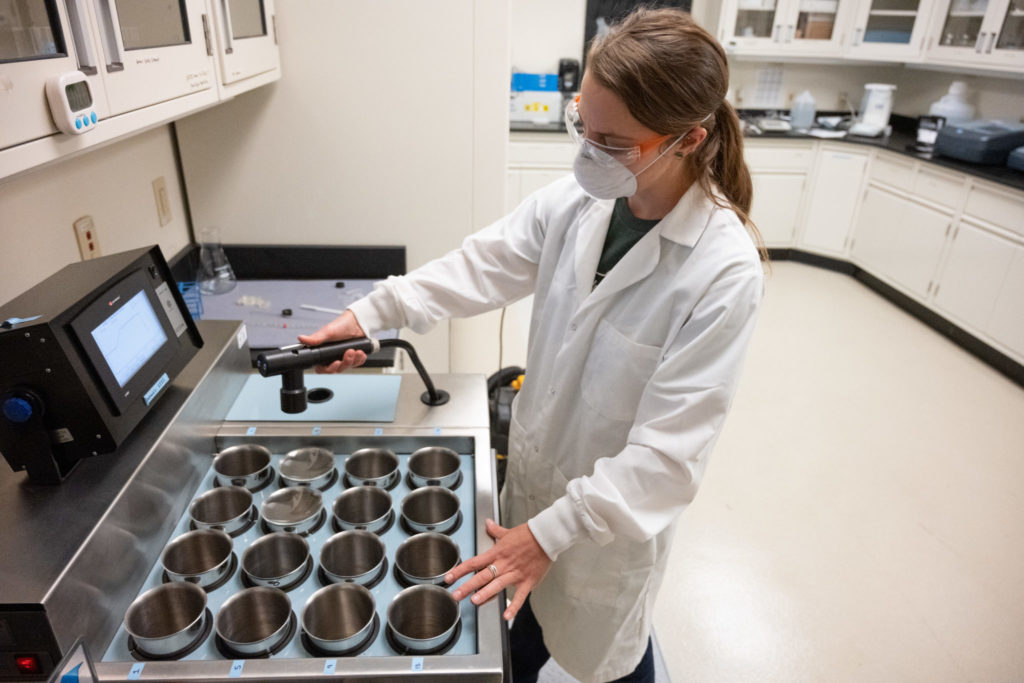

Fromuth noted that students in the FST program can now get hands-on experience with a key step in the “field-to-foam” journey. CSU is building a field-to-foam research institute to support industry along the entire supply/distribution chain.

“It really ties back into the teaching mission,” Fromuth said. “We cover malting in our brewing coursework, but now we can expand that to involve students in actual lab testing, outside the classroom.”

It also exposes students to the malt-testing methods used to create the documentation that brewers use to develop recipes and ensure the consistency and quality of this essential raw ingredient.

“This is a behind-the-scenes look at how those certifications of analysis are obtained,” said Jeff Callaway, associate director of the FST program. “There are a number of ways in which this can affect students positively. They’ll get experience acting as a brewer, using malt they analyzed themselves, but from a client’s perspective.”

One of three nationally

Fromuth said that she is working closely with the two other campuses that have similar labs — Montana State University and Hartwick College in New York — to cross-validate results. She explained that the complete malt-testing process takes about two days and involves assessing 14 characteristics of the malted barley, including protein, color, pH levels, enzyme concentration, sugar content, amino acid levels, moisture, and friability, a grain hardness measurement based on a material’s ability to be crushed. Maltsters can then provide the results of that analysis to brewers as third-party validation of their malt’s properties.

Callaway said CSU recently joined the Craft Maltsters Guild, which provides industry credibility and connects the new lab to the guild’s resources and membership.

“It really plugs us into that network,” he said. “It provides additional resources to new maltsters as well as existing members.”

In addition to the malt-testing lab, two new brewing systems in the Gifford Building are being commissioned, joining the teaching brewery at the Ramskeller Pub in the Lory Student Center to give FST students exposure to the skills and high-tech equipment they’ll use in their brewing careers.

The FST program is in the Department of Food Science and Human Nutrition, part of CSU’s College of Health and Human Sciences.