Colorado State University’s Apparel and Merchandising Program has been a long-time leader in technical apparel development, textile science, 3D technologies, and digital pattern drafting. And in Fall 2023, the Department of Design and Merchandising offered a long-awaited course: shoe design.

Assistant Professor Lida Aflatoony joined the product development faculty in fall 2022, bringing with her an interest and background knowledge in shoe design. After a year of development and collaboration, the course has become a reality.

“Creating and instructing the footwear design course for the first time was truly exhilarating!” said Aflatoony. “Both the students and I shared the excitement of this novel experience—for them, learning a new technique and crafting their own shoes for the first time, and for me, the joy of teaching and personal growth through this unique endeavor.”

Colorado Shoe School collaboration

The process began with some training, learning, and understanding from true shoe experts, right in CSU’s own backyard: The Colorado Shoe School. Established in 2018, the Colorado Shoe School is run by Annabel Reader and Dan Huling (’01) and is located in Bellvue, just north of Fort Collins. They offer shoemaking classes to the public in their own custom-built studio space.

After Reader and Huling toured the Avenir Museum of Design and Merchandising and the Nancy Richardson Design Center in the fall of 2022, Aflatoony and Associate Professor Kristen Morris spent a few days at the Colorado Shoe School taking focused lessons on patternmaking and construction ion for varied shoe styles. This included everything from pattern drafting to material selection, leather dyeing, and constructing the shoe by hammering the leather into the soles.

Through these collaborations, Aflatoony, Reader, and Huling discussed how CSU and the Colorado Shoe School could work collaboratively on a course for shoe design. This arrangement enabled CSU students to visit the Colorado Shoe School and acquire the initial skills in the footwear patternmaking process, calculating the focal points of the patterns and marking them on the covered shoe last. The students drew the various components of the shoe, and then at the CSU footwear design class, they separated each pattern piece, incorporated necessary seam allowances and notches, and ultimately transformed their paper patterns into digital vector-based files, which prepared leather for laser cutting.

Implementing technology and 3D modeling software

Aflatoony infused various modes of technology into the student learning for the course. Much of the construction for the course uses the machinery available in the Nancy Richardson Design Center Fabrication Labs, which provides a large workspace, laser cutters, industrial sewing machines and more to help facilitate construction. In addition, students learned how to develop a 3D model of their personalized shoe sole with Autodesk® Fusion 360™ and 3D print it at Nancy Richardson Design Center Fabrication Lab. Students acquired proficiency in both technological and traditional hands-on footwear manufacturing techniques, enabling them to craft their own wearable footwear items, gaining the skills to incorporate material and color choices, packaging, cost estimation, and technical drawings into professional technical packages.

“My objective throughout this course was to nurture students’ skills in both 3D modeling and handcrafting techniques,” said Aflatoony, “I am pleased to see that both objectives were evident in their final projects.”

Industry insights

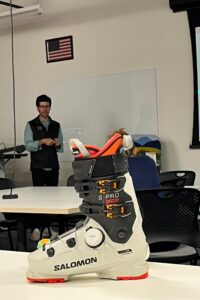

Students also learned about industry technology, specifically for high-performance athletes and use in the outdoors. Aflatoony invited Dan Feeney, Ph.D. and senior director of partner product innovation & development from BOA® Fit System to present his research and work to the class. Many might recognize BOA® Fit System as the handy dial on some ski or snowboard boots that allows the wearer to incrementally tighten or loosen the boot with more ease than tied laces. Feeney’s lab also conducts research into how technology can enhance athletic performance and work to minimize injury.

Wade Motawi, an author of several books on shoemaking and the founder and lead instructor at the Shoemakers Academy, delivered a lecture on strategies for footwear sustainability and the challenges faced by footwear companies in implementing sustainable practices. Throughout Motawi’s presentation, students gained insights into the distinctions between apparel and footwear products, considering factors such as performance requirements, life cycle expectations, packing requirements, material selection, and the impact of sustainability on design.

“I appreciate the chance we had to acquire knowledge from professionals in the field,” said Aflatoony, “we obtained valuable perspectives on practical production methods and the integration of sustainability practices.”

Future of the course

Following the inaugural course’s success, Aflatoony is expanding the footprint of tools and technologies available to students through the Department of Design and Merchandising. Future students will be equipped with additional heavy-duty sewing machines, including a walking foot machine, roller foot free motion machine, zigzag stitch machine, Strobel sewing machine, and a straight arm machine for shoe sole attachment. In addition to sewing machines, the Department of Design and Merchandising is acquiring innovative technologies such as knife cutters and foot scanners to enhance the footwear design course and research in this field. In addition to new fabrication technologies, the course plans to continue building industry partnerships with shoe design companies around Colorado and beyond.

The Department of Design and Merchandising is part of CSU’s College of Health and Human Sciences.