CSU beer experts: ‘Water is everything to a brewer’

Brewers are aware of their water use, and responsible use can serve as a model

Q&A by Mark Gokavi

published March 7, 2024

Perhaps no one is more reliant on high-quality water than brewers. Water makes up more than 90% of most beers. The water flowing from the Rockies is pure and clean, which helps explain why hundreds of macro- and micro-breweries call Colorado home.

“Water is the canvas that the brewer uses to paint, along with malt, hops and yeast,” said Jeff Biegert, Colorado State University’s Fermentation Science and Technology Program instructor and brewmaster, whose position is half funded by New Belgium Brewing. “Water is everything to a brewer.”

The scarcity of water in Western states affects agriculture, population, rural communities, infrastructure, industry, the economy, climate, wildlife and more.

“In the face of water challenges in the Western U.S., breweries are increasingly cognizant of their water usage,” said Charlie Hoxmeier, an assistant professor at CSU and head brewer at Gilded Goat Brewing Company. “Many are implementing water-saving technologies, optimizing processes and reusing water where possible.”

Brewing in Colorado is a more than $3.2 billion industry with more than 400 breweries. In 2016, Colorado had the second-most brewery jobs after California, and the state is home to major employers such as MillerCoors and AB InBev.

Biegert and Hoxmeier addressed how much water is used to brew beer, water conservation efforts at big and small breweries and how long craft breweries have valued sustainability.

How do brewers optimize water use?

Biegert: All large brewers and most of the smaller ones reclaim hot water from a critical cooling step in the brewing process for use in subsequent brews. There are numerous areas where water use can be optimized, specifically in cleaning and sanitation, utilities, and in packaging. Brewers also monitor and optimize the yield of raw materials, specifically malt, to produce beer with minimal waste.

How important is water caliber to a brewer?

Hoxmeier: Water quality significantly influences the taste, aroma and overall characteristics of our final product. Brewers pay meticulous attention to water profiles, ensuring a complementary mineral content and pH for each beer to drive flavors but also to help manage the delicate biochemistry that is occurring during the brewing process.

What makes Colorado water so good for beer?

Biegert: The water on the Front Range is primarily first use, meaning water from the rivers running off from the Continental Divide. This water is exceptionally low in mineral content and considered “soft,” and it is highly suitable for brewing crisp, clean lager beer. Soft water is also easy to build upon by the addition of minerals for brewing many other types of beer.

“This water is exceptionally low in mineral content and considered “soft,” and it is highly suitable for brewing crisp, clean lager beer.“

—Jeff Biegert, CSU’s Fermentation Science and Technology Program instructor and brewmaster

How much water is needed to brew a gallon of beer?

Hoxmeier: Large breweries are more efficient with their water use due to highly automated production methods that have reduced their water-to-beer use ratio down to two to four barrels of water to produce one barrel of beer. The small brewers use about 10-20 barrels of water to produce a single barrel of beer.

How else do brewers conserve water; what could get better?

Biegert: Other ways include re-use of rinse water and chemicals in tank cleaning processes, using dry lubricants on packaging lines, reusing or eliminating rinse water used for containers (bottles/cans) on packaging lines and the reclamation of water used to condense steam in the brewing process.

Hoxmeier: Future improvements could involve advanced water treatment technologies and smart water monitoring systems, and some not-so-standard practices may involve on-site wastewater treatment systems where the brewery reuses treated water.

Is the brewing business ahead in water conservation?

Biegert: While I cannot speak for other industries, I can say for any manufacturing facility, reduction and reuse of water is not only sustainable, but it can also be profitable. From my perspective, New Belgium Brewing was really the leader in this area for craft, starting with NBB’s original core values and beliefs from 1991 that included specifics such as environmental sustainability and continuous improvement.

Hoxmeier: The brewing industry has shown leadership in water conservation in many ways. This priority emerged as breweries recognized their environmental impact and the importance of sustainable practices and protecting our watershed for future generations.

SOURCE Special Report: Solving the water crisis

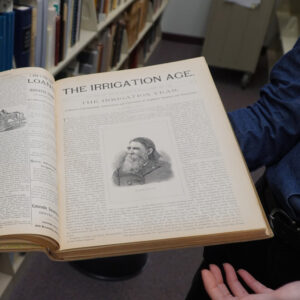

CSU has been at the forefront of hydrology for more than a century since Elwood Mead, the namesake of America’s largest reservoir, became the first head of the Department of Civil and Environmental Engineering in 1883. This special report from SOURCE explores the research happening at CSU and provides insights into the ongoing water crisis across the country and around the globe.